TIMBER

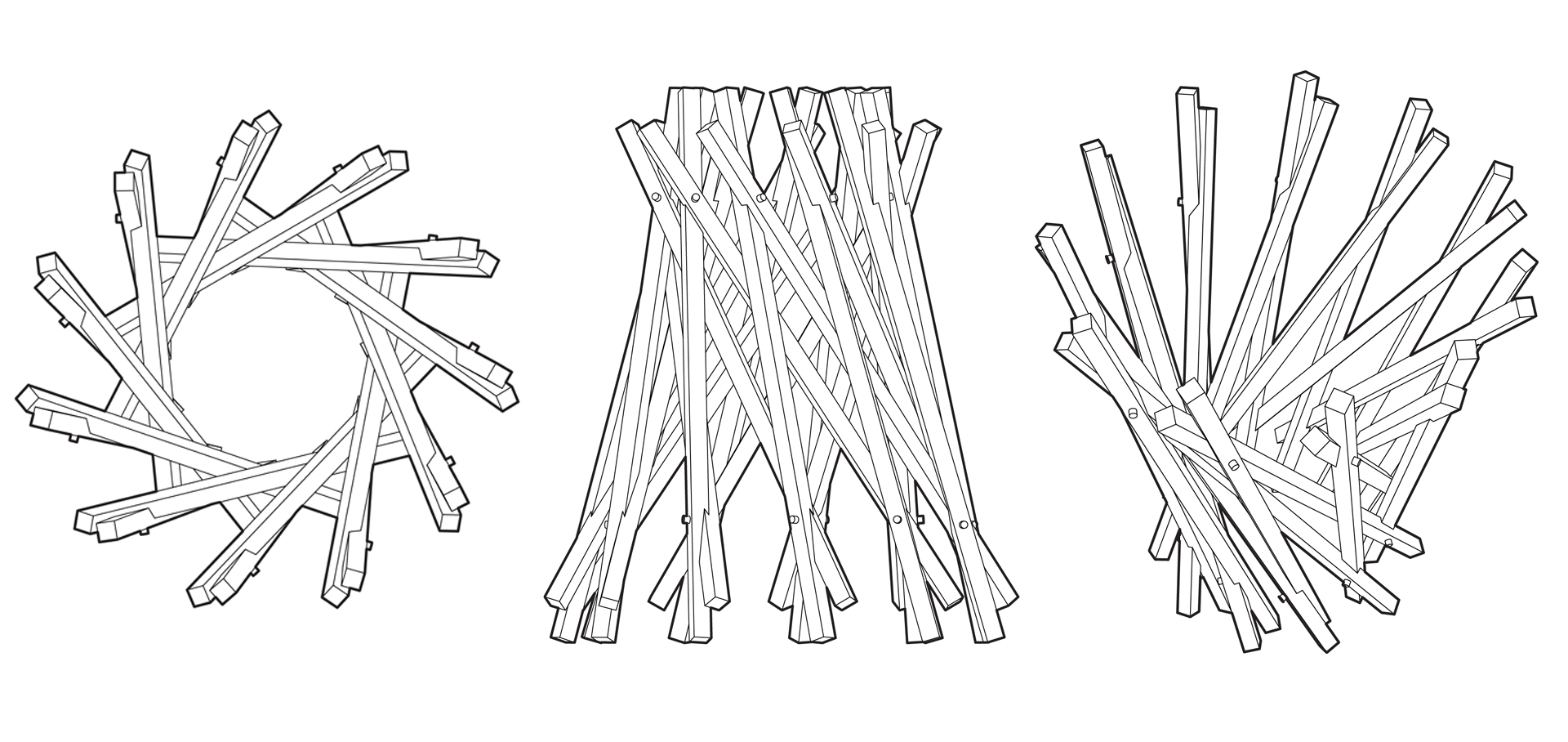

Timber focuses on the robotic handling and machining of timber members, to ultimately create a self-supporting frame using complex three-dimensional notches.

HOW IT WORKS

For this project, I developed two scripts in Grasshopper. The first evaluates the geometry of a 3-D model of a timber member. The second using information from the first script, outputs the robotic tool paths and code needed to machine that member with all of its detected features. In the case of this project, it was a 4-foot member with a notch and a hole. This, tied together with taught material handling procedures, my group and I set out to create a circular, reciprocal wooden frame. Again, using Grasshopper, we generated a frame that closes in on itself, which makes the frame self-supporting.

We ran into a few errors along the way in regards to machining accurately with the two robots, and moving from 3-D digital space into the real world. It took us about 8 attempts before we achieve the accuracy we wanted. After the robotic machining, we moved to our wood shop to do some post processing on the stick, Due to the complexity of the frame, it took us two attempts to assemble, but once we figured the correct way to assemble, it worked flawlessly.

This project was done with Jose Pertierra and Tony Zhang.